Ultra-Precision Processing Technology

Ultra-Precision

Diamond

Turning

Single Point Diamond Turning

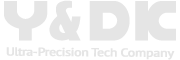

Ultra-precision diamond turning is a method of rotating workpieces using diamond tools with very sharp tool edges, and is used to produce ultra-precision optical components such as off-axis parabolic (OAP) mirrors, off-axis elliptical (OAE) mirrors, spherical & aspheric lenses, and flatwork. Processing technology used to manufacture

Diamond Turning Machine

Joint use of KBSI equipment

Nanotech 450 UPL

| Model | Nanotech 450 UPL |

|---|---|

| Performance | Ra ≤ 2.0 nm |

| PV ≤ 0.125 ㎛ | |

| Swing Capacity | Up to 450 mm diameter (without risers) |

| Working Load Capacity | 85 Kg (185 lbs @ 100 psi.) |

| Motion Accuracy | Axial ≤ 12.5 nm |

| Radial ≤ 12.5 nm |

Freeform 700 A

| Model | Freeform 700A |

|---|---|

| Performance | Ra ≤ 4.0 nm |

| PV ≤ 0.15 ㎛ | |

| Swing Capacity | Up to 700 mm diameter (without risers) |

| Working Load Capacity | 68 Kg (150 lbs @ 100 psi.) |

| Motion Accuracy | Axial ≤ 25 nm |

| Radial ≤ 25 nm |

Freeform L 1000

| Model | Nanoform L 1000 |

|---|---|

| Performance | Ra ≤ 1.25 nm |

| PV ≤ 0.125 ㎛ | |

| Swing Capacity | Up to 1,000 mm diameter (without risers) |

| Working Load Capacity | 170 Kg (375 lbs @ 100 psi.) |

| Motion Accuracy | Axial ≤ 30 nm |

| Radial ≤ 30 nm |

Magnetorheological Fluid

Polishing

Magneto-Rheological Finishing

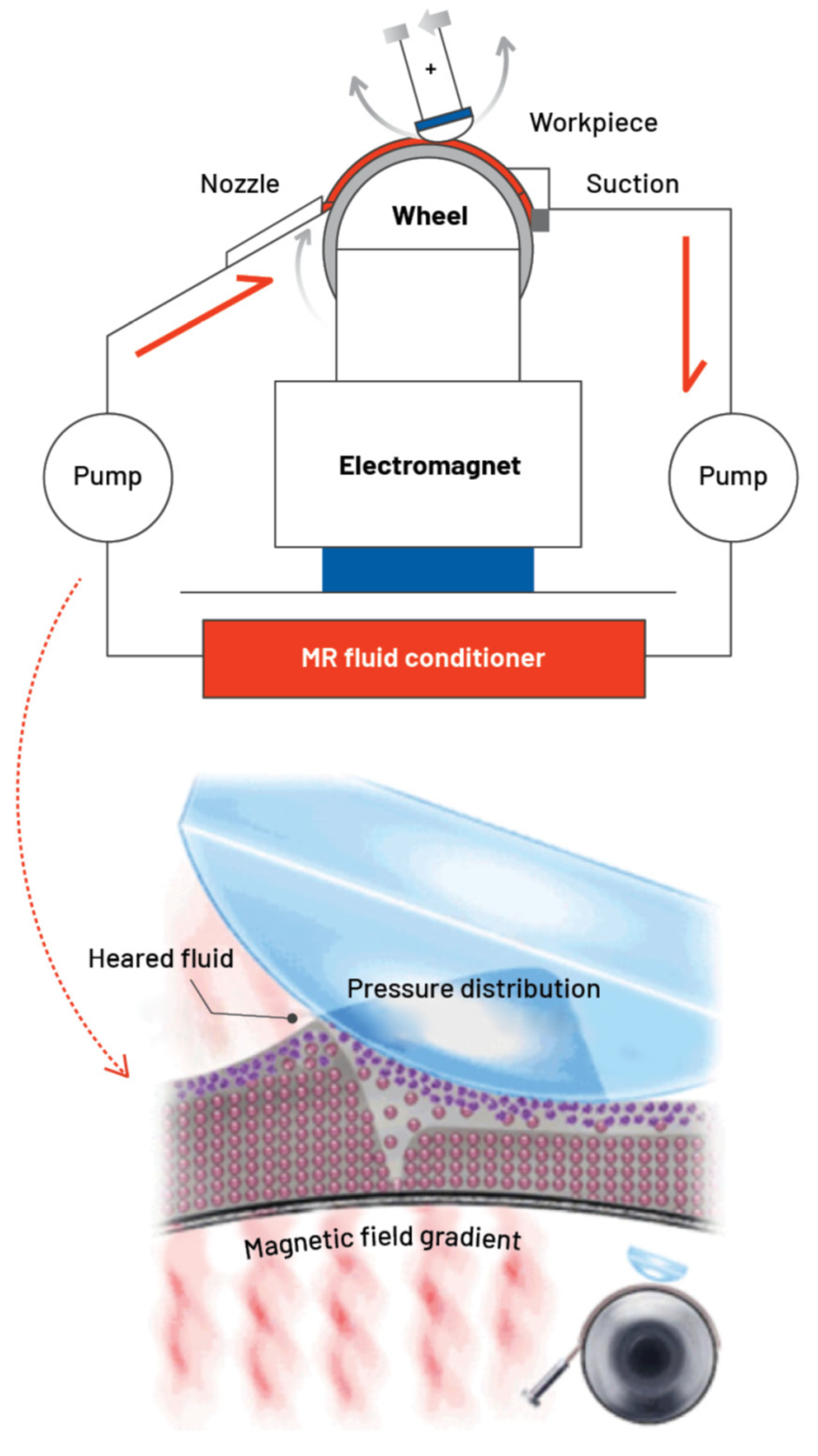

Magnetorheological fluid polishing is a process based on Bingham fluid, whose properties change depending on the presence or absence of a magnetic field, and is a technology used to manufacture ultra-high precision surfaces of optical components made of glass, ceramic, metal, plastic, etc.

Magneto-Rheological Finishing

Joint use of KBSI equipment

Q-Flex 300

| Model | Q-Flex 300 |

|---|---|

| Performance | 300 x 300 mm (larger parts achievable depending on geometry) |

| Working Load Capacity | 18.8 kg |

| RMS | < 1nm @ on most materials with any MR fluid |

| < 0.5nm @ on most glasses and singles crystals with specific MR fluid | |

| 0.1 - 0.2 nm on some materials with specific MR fluid | |

| Peak to Valley | < λ/30 - λ/40 |

Q22-1200F-PC

| Model | Q22-1200F-PC |

|---|---|

| Part size up to | 1200 x 1200 mm (larger parts achievable depending on geometry) |

| Working Load Capacity | 400 kg |

| RMS | < 1nm @ on most materials with any MR fluid |

| < 0.5nm @ on most glasses and singles crystals with specific MR fluid | |

| 0.1 - 0.2 nm on some materials with specific MR fluid | |

| Peak to Valley | < λ/30 - λ/40 |